Hi Pen Fans!

Topics covered in this blog….

1. The Mina can be a bulb filler, but no ink window…(yet?)

2. Discussion around the size of the Mina.

3. New Overlay Pen Coming!!!

Links mentioned in the video with good Mina comparison photos….

Thanks!

Hi Pen Fans!

Topics covered in this blog….

1. The Mina can be a bulb filler, but no ink window…(yet?)

2. Discussion around the size of the Mina.

3. New Overlay Pen Coming!!!

Links mentioned in the video with good Mina comparison photos….

Thanks!

Hi Pen Fans,

A New Pen Model!!!!

Links mentioned in the video….

New #5 Nibs – 18k, Steel, and Wide Italics

Thanks!

Hi Pen Fans.

The vast majority of my business without a doubt is fountain pens. But I do get plenty of orders for rollerballs.

In the past, my rollerball sections have been fine. They were injected plastic, always black with gold or rhodium trim. Nothing wrong with this at all. But here’s what I didn’t like about them….I was not manufacturing them. I was outsourcing the sections. When possible, I really like to make sure that I manufacture every part on my pens, with the nib and usually the clip being obvious exceptions.

Well, I recently was able to devote some time to perfecting the manufacturing of my rollerball sections.

When I manufactured these, here’s the changes that I made…

The new rollerball sections are not limited to black. I can now make a rollerball section to match the material of the pen. In my opinion, this makes a huge difference in the overall look of the pen.

The section is more slender. The old rollerball sections were a little thick and clunky.

The rollerball refills are Schmidt 5888’s, and Schmidt 888’s, which have always been my favorite. In mediums, I have Blue, Black, Red, Green, Turquoise, Magenta, Purple, Orange, and Light Green. In fines, I have Blue and Black. I’m looking for even more selection.

For those who prefer a ballpoint, I have only a medium point black refill for now.

Below is a photo of a Morgan rollerball in Red/Black ebonite with the new section.

.jpg)

The metal tips can be gold or rhodium to match any material.

I’ll be adding more and more photos to the Rollerball Page very soon, but in the meatime, any of my pens can be customized to become a rollerball, and any material that we can dream up can be used.

I also have rollerball refills of various lengths. If someone wanted to customize a pen to be shorter, like a pocket pen or a smaller pen for a purse, we can customize in any way.

As a special introductory price, I’m going to sell these through the month of October for $175.

Then beginning in November, price will go to $200. These prices are the same for any model of pen that you might be interested in.

Additionally, I had someone ask a good question…These rollerball sections will fit into my fountain pen bodies. So if you wanted to buy a fountain pen that would have an extra rollerball section, this is no problem. I haven’t determined the exact price of the rollerball section only, but I will soon.

Please email me if you are interested.

Thanks

Hi Pen Fans.

In the past, I’ve had cast sterling snake clips, but truth be told, I was only OK with their designs.

I recently enlisted the help of a friend to create some custom snake clips to my specifications and design.

I couldn’t be happier with how they turned out.

They wrap around the cap of a Huron or Glenmont. Since they are not attached all the way around the cap, they are adjustable to a degree to make a perfect fit.

They are probably not all that functional, outside of keeping a pen from rolling off of a desk. They are more decorative. I wouldn’t recommend slipping the clips over a real thick pocket, as they might bend. However, being sterling silver, they can easily be moved back into tension.

The clip is shown below in a black acrylic pen with a satin finish.

Being silver, I don’t recommend these clips going onto an ebonite pen. The ebonite outgassing will tarnish the clip. However, the black acrylic that you see above is a perfect “faux” ebonite. It’s rather soft, and not at all brittle like most acrylics. When a pen is finished in this acrylic, I can’t tell the difference between this and ebonite without smelling.

This clip looks great with black acrylic. I have trouble picturing this clip on something with grain, or a wild material, as your eye would be divided between the material and the clip. However, I can see this clip with some other solid colors…blue, red, green, etc….

These clips will add $90 to the cost of a pen.

Thanks for looking!

Hi Pen Fans!

I am proud to introduce two new pen models.

I have created larger versions of the Herald and Huron.

These will be known as the Huron Grande and Herald Grande.

Here is a slideshow showing the Huron Grande…..

(if you cannot see this slideshow, click here)

…and a slideshow showing the Herald Grande….

(if you cannot see this slideshow, click here)

These are both pretty large pens, at 6 1/2" capped, and 5 3/8" uncapped. But still not overly heavy at around 26 grams capped and 15 grams uncapped.

Here is a photo showing how these new pens stack up next to my current line….

.jpg)

These Grande pens are both avalable as fountain pens, but I will have a rollerball option coming soon.

I do have some of these pen in inventory, ready for immediate sale. Click here to see my current inventory.

Please click these links to learn more about these pens.

Thanks,

Hi Pen Fans.

I’m pround to announce a collaboration between Edison and Chatterley Pens.

In about 2 weeks, I will officially announce "Grande" versions of a couple of my pens.

As the name implies, these will be larger versions.

I have completed an early Limited Edition of 18 Huron Grande pens for Chatterley Pens. These pens are made from Ivory Celluloid.

This Ivory Celluloid is getting scarce, and will be completely gone very soon, if it’s not already gone from my supplier.

This is a larger pen, at about 6.5" capped, and 5.5" uncapped.

This pen in Ivory Celluloid will only be available from Chatterley Pens. They are not for sale here. I will not be making anymore Huron Grande pens from this Ivory Celluloid.

Please visit Chatterley Pens at www.pentime.com for more more details.

Photos are below, courtesy of Chatterley Pens.

Thanks,

Hi Pen Fans!

I always love it when a customer approaches me with new ideas, designs, filling systems, and challenges to consider.

I had a customer speak to me about a blow filler.

This is a filling system that was used very early in the history of pens. I’m not sure that it was a real lucrative filling system, as I’ve never seen one live, but it turned out to be very interesting and certainly fun.

With a blow filler, there is a sac attached to the section or housing which holds the ink. This is just like any other typical pen incorporating a sac as the reservoir, such as a lever filler, button filler, crescent filler, etc.

Each of these sac filled pens incorporate some way of compressing the sac. When you dip the pen in ink, compress the sac and then release, the result of the sac returning to it’s shape will cause a vacuum resulting in ink being drawn into the sac.

In the case of a lever filler, there is a pressure bar that compresses the sac, activated by a lever. With a button filler, there is a pressure bar activated by a button on the bottom of the pen, with a crescent filler, the same applies, and you can guess what activates the pressure bar.

So this pen fills the same way, but with an incredibly simple method of compressing the sac.

How does this pen fill?

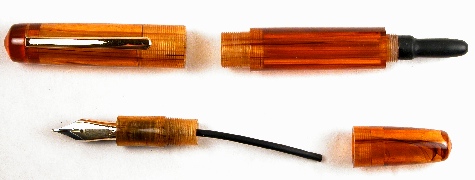

There is a very small hole drilled into the bottom of the barrel, which is visible in the photos below.

The section threads are made very precise, to the point of where they are airtight.

This seals the barrel internally.

So to fill the pen, you insert the nib into an ink reservoir, and blow into this hole on the back of the barrel.

Since the interior of the barrel is sealed, blowing into the barrel increases pressure, causing the sac to compress.

When you stop blowing, the sac decompresses, drawing ink into the sac.

Two or three cycles of blowing into the back of the barrel will fill the pen completely.

The blowfillers of the past would typically not have an ink window. The customer who ordered this pen wanted some kind of way of knowing where the ink level was. We went with an ink window, and also a clear sac. This makes it easy to determine when it’s time to refill.

This pen was also made from original Sheaffer Crimson stock. Very hard to find.

This was a seriously fun pen to make. It was really nice to revive a design from a very long time ago!

Hi Pen Fans!

I’m proud to introduce my newest model, The Morgan.

(if you cannot see the slide show above, click here)

I’d like to discuss a little about its design.

I have a lot of clients who love the Pearl, but prefer a pen that is longer, and posts more secure. This has been made evident by the number of custom Pearls that I’ve made to be extended in length.

This pen is one of my longer offerings, at 6" capped. The extra length allows me to create a very elegant profile that allows for secure posting.

This pen is offered standard as a cartridge/converter, but can be made into a bulb filler, and also a rollerball.

Obviously, the pen is available in the materials shown on the Morgan Main Page, but any custom material that you and I can dream up is available.

Please go here for more details.

Thanks,

Hi Pen Fans.

When I went to the DC pen show, I had two special pens that I brought with me. One was a Pearl Bulb Filler, and one was a #76 Bulb Filler. They were both custom commissions. One was for a customer, and one was for the Cherished Creations Charity Auction (which was a smashing success, by the way).

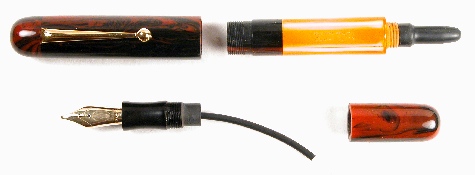

I’ve made bulb fillers before. What made these pens unique was the fact that the barrels were made from a translucent material, in the spirit of the old Postal Pens.

Well, they were such a hot item, that I’m just now finishing up the orders from the DC show. 90% of the orders that were placed were for these bulb fillers.

Unless I’m mistaken, I’m the only modern pen manufacturer who is creating a bulb filler. There are a couple of things that make these pens unique. The mechanism has no moving parts to break down. Long term, this will be a very reliable filling mechanism. The only part that could fail would be the bulb sac, which is easily replaced. The ink capacity is a whopping 2.5 to 3 mL. The ink window will obviously tell you when it’s time to refill. And lastly, seeing the pen fill is just plain cool!

Here is a video of a bulb filler pen being filled.

You will notice that some of the translucent barrels are tinted. I have tinted barrel material in a myriad of colors, so matching a translucent barrel to any material type or color is possible.

Any of my pens can be made into a bulb filler, which the exception of the Herald. I don’t think that the taper of the Herald’s barrel will accommodate the bulb mechanism (but I haven’t tried yet). I have not made a Huron into a bulb filler yet, but I can’t wait to.

After putting together a decent collection of these, I thought that I would present photos of them.

Pearl Bulb Fillers…

Hunter Green Acrylic

Black Rose Acrylic

Tortoise Lucite

And #76 bulb fillers…

Tortoise Lucite

Granite Acrylic

Mandarin Yellow

Black Rose Acrylic

And here is a complete slideshow of the recent pens (press play to start the slideshow).

The price of making any pen into a bulb filler adds $75 for an opaque barrel, and $100 for a translucent barrel.

Email me if you have any questions.

Thanks for reading!

Hi Pen Fans!

I’m proud to introduce my newest model, The Huron.

I’d like to discuss a little about its design.

On most of my pens, the design calls for a step from the barrel to the barrel threads. A good example of this is the Pearl. The Pearl has a dramatic step from barrel to barrel threads. It is an integral part of the design.

Some customers have told me that they would prefer that this step was not present on their pens. With this in mind, I have designed the Huron.

The transition from the barrel, to the barrel threads, to the section is smooth and seamless. The section is also longer and less dramatic in it’s curve. The clip sits a little lower with a larger finial. All of this leads to a pretty slender and elegant design, similar to early American pens.

When prototyping this pen, I was seriously torn between two clips.

I did some market research by sending pictures to friends, collecting opinions on the webcam, and posing this clip dilemma to people whose opinion I trusted.

The opinions were so extremely polarized, that I was only further perplexed.

I started thinking…"I’m a custom penmaker, right? Why not offer them both?"

So with this pen, the customer will have a choice of two clips. There is a segmented clip, as well as a straight clip, as show below.

Both of these clips are available as rhodium or gold plated, however…the straight clip with gold plating will not be here for another couple of weeks, as they need to be plated.

Obviously, the pen is available in the materials shown on the Huron Main Page, but any custom material that you and I can dream up is available.

Please go here for more details.

Thanks,